Fix odour problems

The fine-bubble ventilation combats odour formation at the point of origin:

The reduction of odour emissions from sewer networks due to long residence times of wastewater is a problem for operators of extensive sewer networks. Drausy® is efficient and sustainable as a measure for the aerobic operation of pressure pipes.

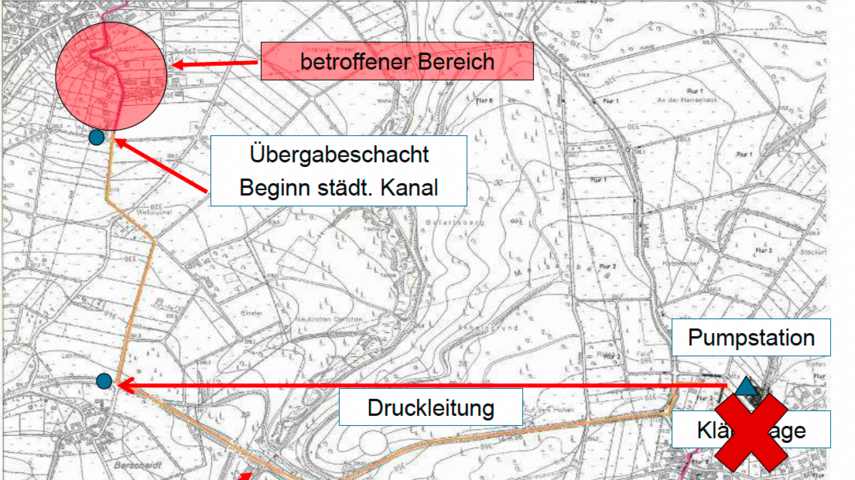

Localise odour formation

The height profile of the pressure line is crucial:

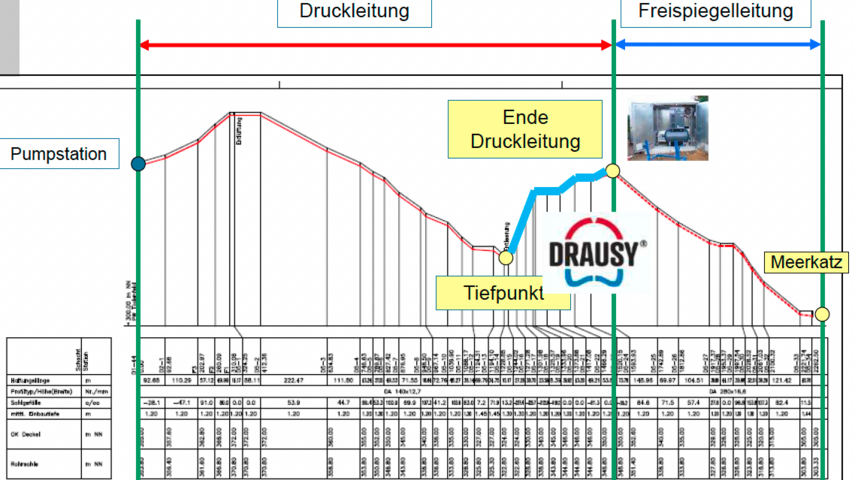

If odour occurs from a transfer shaft, the cause of the odour formation is often in the pressure pipe - every pumping run and every afterblowing leads to a measurable H2S surge. Height differences and pumping times/volumes are relevant for assessing the application of the Drausy® system in the pressure pipe.

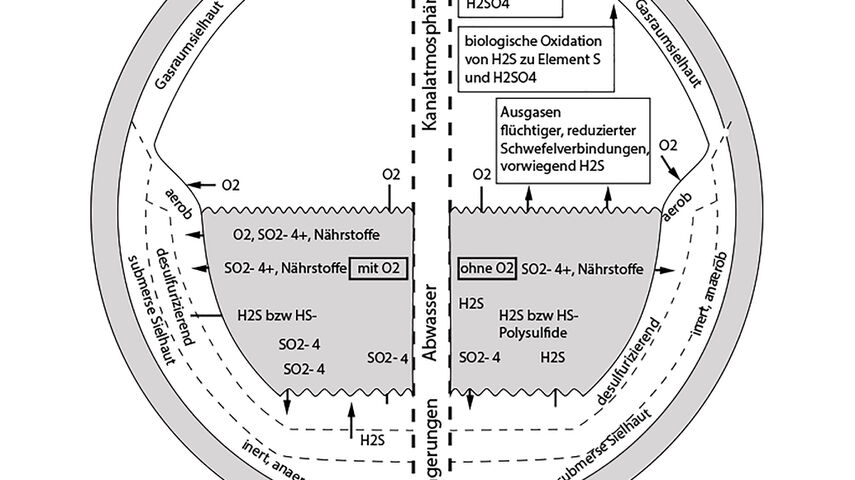

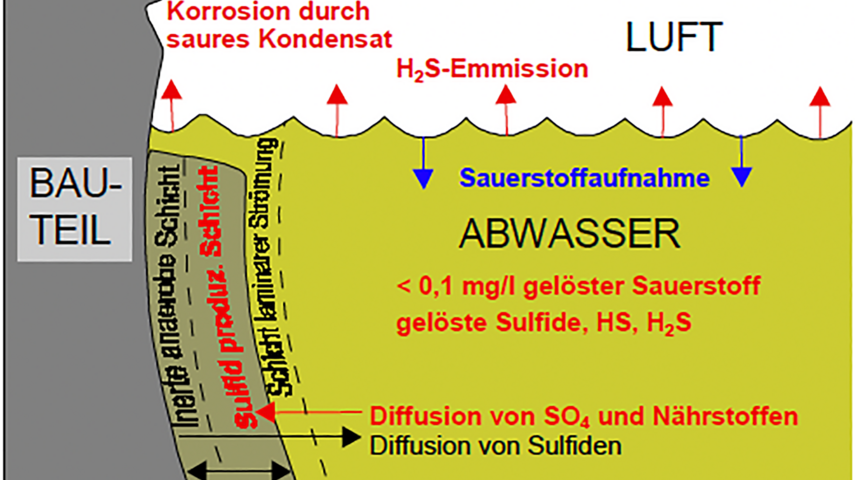

Tackle the cause

Keeping wastewater fresh through aerobic conditions:

Long standing times in the pipe lead to oxygen depletion - the mixing of wastewater streams with different ph values results in the local release of H2S. Aeration directly in the pressure line eliminates these problems immediately and permanently.

Keep waste water fresh

Through the targeted use of Drausy® aeration in the pressure line, odours are successfully and permanently removed without additives:

The intensity, location, frequency, duration and characteristics of the odour nuisance must be checked by an expert. By analysing measurement data and examining the longitudinal sections of your facility, we can make a recommendation for the use of the Drausy® system.

Relevant odorous substances

Substances perceived as unpleasant - hydrogen sulphide, ammonia, butyric acid, trimethylamine and skatole:

The guiding parameter of odorous substances is hydrogen sulphide (H2S) - Sources of sulphur compounds in wastewater: urine, faeces, detergents as salt or surfactant, kitchen waste and pre-contaminants in drinking water. Sulphur compounds from food: Beer, potatoes, onions, corn, rice, fish and yeast.

Track ventilation system

The fine-bubble ventilation has a uniform effect along the entire paving section:

The linear system can be installed in the rising pressure line. Automatic programming allows the period of air bubbling as well as pause and runtime control to be freely selected. An interlock of the compressor against the pumps secures the system.